What Are embedded RFID tags?

Embeddable RFID tags are designed to be embedded into an object rather than simply attached to the surface.

DO RFID tag manufacturer's Embeddable RFID tags are available in different form factors for use on various assets.

Hard Metal Mount RFID tags are designed for embedding into metal assets or tools. RFID tags embedded in metal must be completely covered by metal in order to function.

Non-Metal Mount Hard RFID Tags - Designed for embedding into non-metallic materials such as plastic, wood, and glass.

RFID Laundry Tags - Specialized for embedding into fabric by sewing a pocket in the fabric on all four sides.

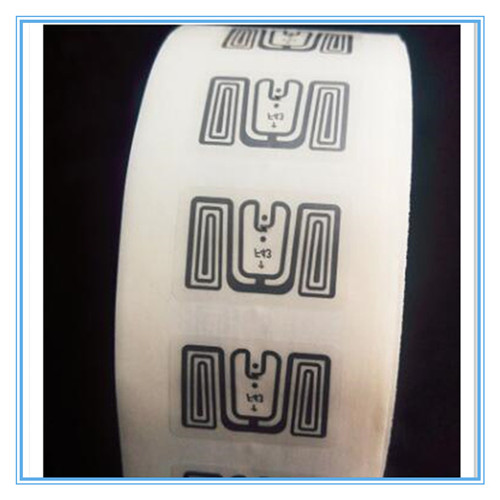

RFID Dry Inlays - RFID Dry inlays can be embedded in the paper, cardboard, wristbands, cards and badges, and so on.

RFID Animal Tags - RFID Animal tags can be embedded in animals to identify livestock or animals.

Why are RFID tags embedded?

There are tagging scenarios in which embedded RFID tags are used.

Functionality has been compromised.

If placing an RFID tag on the surface of an item would interfere with its use or functionality, embedding the RFID tag is probably the best option. Tagging tools are one of the best examples of this. Most hand tools, regardless of industry, will need to be used frequently, and an RFID tag mounted on the surface would impede their use. Embeddable tags are frequently used to track tools like scalpels, wrenches, hammers, and even landscaping equipment.

Protection

Embeddable RFID tags are also frequently used in harsh environments where the RFID tag could be knocked off the asset's surface and lost. This could be due to machinery, proximity to other assets, or even extreme weather. In these cases, the RFID tag must be protected, and embedding is one of the best ways to do so.

Concealment

Another scenario in which embeddable RFID tags would be useful is if the application was customer-facing and the tag could be damaged or removed by individuals. Inventory tracking in retail stores is one example of this. Manufacturers who tag clothing to improve inventory management typically embed the RFID tag inside the sales/price tag. Most customers do not disturb these tags because they are not easily seen or recognized, and they can be easily removed after purchase.

Important things for Custom embeded RFID tag

1. When drilling or creating a hole for the RFID tag to reside in, it is important to only make the hole as deep as the tag’s height. The RFID tag should always be flush mounted on the asset so that the Face is level with the asset’s surface.

2. The RFID-embedded tag should be covered on all sides and the bottom face, exposing the top face for reading.

3. Most manufacturers suggest custom the embedded RFID tag for the longer side of the asset as opposed to the shorter side. This is because metal-mount RFID tags are designed to use their immediate surface as an extension of their antenna. The longer their immediate surface, the longer their antenna and the longer the tag’s potential read range.

4. Do not use a Metal-Mount RFIDTag on a Plastic Asset, and Vice Versa. During the manufacturing process, an RFID tag’s antenna is tuned and designed to work on specific materials in order to maximize its read range. When the RFID tag is not mounted on the type of material suggested, the tag’s antenna does not function as well, and the read range is greatly diminished. In some cases, the tag will not work at all

.Consumables like filters, cartridges, or gas cartouches

Medical tools (e.g. drills)

Cable plugs

Car keys

Plastic boxes for the transport of goods

Branded merchandise

carbon frams

Selection of Short RFID tags for pallets

Let's us know if you didn't find out what you need.

GEN2 UHF High Temperature RFID tags

It can be mounted on any surface and supply long read rangeView Details

GEN2 UHF On Metal RFID tags

GEN2 UHF On Metal RFID tags are ABS anti-metal tags and PCB anti metal tagsView Details

GEN2 UHF RFID laundry tag

There are flexible and elastic silicone RFID Laundry Tags ...View Details

GEN2 UHF Animal RFID tag

GEN2 UHF RFID animal tags help manage and safeguard livestock ...View Details

Rugged RFID tags

EPC GEN2 Rugged RFID tags has been tested in several applications. ....View Details

RFID Windshield tag

The RFID Windshield tag is designed to be attached to optimization. ....View Details

Smallest RFID tags

We developed the mini RFID tag is the world's smallest rfid tag for many applicationsView Details

Request A Quote or Samples