Fashion companies use RFID to optimize operations

NTK Confecções is a clothing company located in Sao Paulo, Brazil, operating brands such as Fatal for young consumers. The company deployed RFID technology from an RFID smart label company in May 2021. A few months after successfully deploying RFID, the company decided to expand the deployment to all areas of its business.

NTK Confecções was established more than 20 years ago and now has 280 employees and produces 350,000 garments per month. According to NTK’s logistics and operations manager Eduardo Agenor Leite, “The technology has been used in its radar field for more than two years before NTK applied RFID to its operations.

However, the market seeks to get twice the result with half the effort. There are resources to do more, and RFID is part of the company’s strategy."

Wright said his company has made great progress without much technology. Now, in order to continue this development, they need to invest in more technologies including RFID. So over the past two years, the company has been planning to carry out business transformation with its RFID partners. NTK's physical architecture will be implemented in December 2020, and the iTAG system will be integrated with its enterprise resource planning system in March 2021.In May of this year, NTK began to put labels on its outfits. Wright said, “Assembling the kit is to optimize the cost, so each kit containing six pieces has a tag. Not all areas of the company have already used RFID, and some areas are still adjusting the process to implement the technology. RFID will help. To make these processes safer. In May, we began to use RFID extensively. The previous operations of entering, counting, and going online for 1,000 garments took an hour. Now with RFID, we can complete it in less than 10 minutes. These operations. This greatly simplifies our business processes."

NTK's management decided to start using RFID technology in the spring and summer and autumn and winter fashion seasons. Wright said, "RFID technology effectively contributes to information security. In this way, we can ensure that the correct product is sent to each customer's order. In each process, the error rate of RFID is zero."

The next steps include managing the goods through product invoices. Wright calculated that 50% of the company's employees are currently using RFID. "We still haven't used it for storage and distribution to warehouses. We produce 45,000 products every day. I believe that by the end of 2021, we will be able to use RFID in 80% of our business. The biggest challenge in implementing this technology is that research must be modified. The existing process and the convenience brought by the implementation of the RFID system is one of the benefits of this transformation."

RFID long range Reader

Thes RFID reader purposefully designed to deliver industry-best read rates and accuracy for the highest volumes of tags in the most challenging RFID environments,...View Details

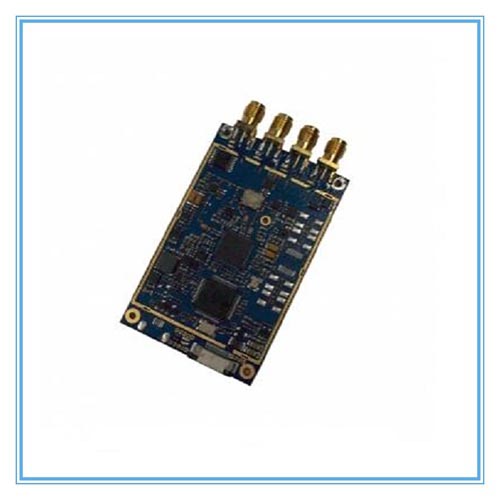

UHF RFID Reader module

UHF UHF RFID Reader module, as a high efficiency and low cost, UHF tag reading/writing module...View Details

USB UHF RFID Reader

Desktop USB RFID UHF reader writer is portable rfid reader writer for program and encode....View Details

EPC Gen 2 RFID reader antenna

EPC takes full advantage of the higher UHF bandwidth by supporting reading multiple tags at once,...View Details

UHF RFID Reader

The UHF RFID reader with RFID antenna can be transmitted data over a distance of over 10 m,...View Details

EPC Gen 2 tag

EPC Gen 2 tag follows ISO/IEC 18000-6C, EPCglobal Class 1 Gen 2, chip including Alien H3, Impinj M4 M5,NXP UCODE.....View Details

Request A Quote or Samples