What is the RFID tag for pallet ?

In recent years, the smart supply chain has adopted rfid tags for pallets, installed the RFID tags on each pallet in the warehouse so that it can clearly know where it is going, and cooperate with automatic guided vehicles (AGV) forklifts ,automated shelving and storage systems use to improve accuracy and reduce losses.

By installing UHF RFID readers at the entrances and exits or key points, these long range RFID readers can read pallets RFID tag in batches, and quickly and accurately know the number of delivery or receiving pallets, using pallets RFID tags for pallets can improv inventory and usage accuracy and track and traceability.

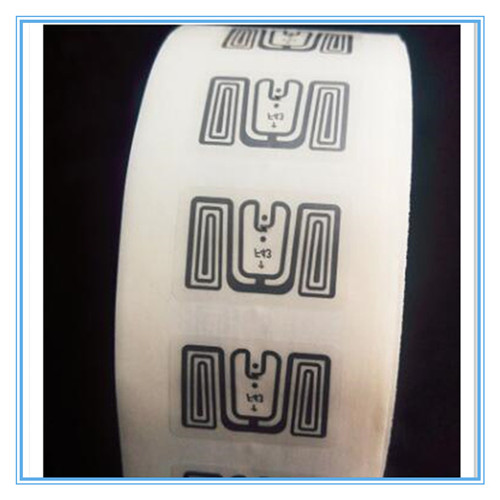

Pallets RFID tags are passive UHF tags, GS1 EPC Class 1 Gen 2 compliant, operating frequency from 860 MHz to 960 MHz, they offer 100,000 write lifetimes, data retention up to 50 years, and can cover up to 30 feet (10 meters) read range. Each RFID tag for pallet has a unique serial number wich is best use for supply chian tracking.

According to the different products you want to track, DO RFID TAG manufacturers developed different RFID tags, such as waterproof RFID tag , shockproof RFID tag, anti-metal RFID tag or anti-high temperature, RFID tags or one-time low price RFID tag. Each pallet RFID tag has a user memory, which can be programmed with relevant information. In addition, QR codes can be printed on the surface of pallets RFID tags. It has many mounted methods, adhesive or screw .

RFID tag for pallet can store more information than barcodes and allow you to access that information and information about multiple pallets at any time. So it's easy to see how quickly this method of marking and sorting can simplify your workflow and pallet tracking process.

The main advantage of pallet RFID tag is that it brings transparency to the entire supply chain with relatively little labor investment. Instead of scanning every SKU on every carton, the person loading or unloading the truck can simply scan or record the pallet-level tracking number. When this information is logged into the database, it is possible to find out not only where the product pallet is currently, but where it used to be.

Why choose RFID tag for pallets?

RFID tag for pallets are an advanced and efficient method of warehouse pallet tracking that, when implemented properly, can significantly simplify your logistics. RFID (Radio Frequency Identification) tag in the form of RFID plastic pallets, is a way to clearly identify your pallets and goods and their location in the supply chain and speed up the transfer and receipt of goods.

How does RFID pallet tracking work?

Currently, you can use barcodes or labels on pallets to track your inventory or shipments, but RFID pallet tracking technology is much more efficient. Bar codes and labels can be difficult to read and do not store large amounts of data. Since the opportunity to scan barcodes or record label information may be limited, you may not know the exact location of your pallets for a long time. RFID revolutionizes these constraints. DO RFID tag developed the RFID tag with light that lights up once it is scanned, allowing you to see its location intuitively.

How to use RFID tag for pallets

You simply attach the RFID tag to the pallet and upload the information about the shipment to the database. RFID pallet tracking tags activate in response to radio waves projected on them, using these waves to generate a magnetic field to power themselves.

Your pallets become instantly identifiable, and you can track the inspection, movement and receipt of goods in clear, real-time anywhere in the supply chain, avoiding logistical clutter and minimizing the chance of lost pallets.

When attaching RFID tags to pallets, be sure to place them where they can be easily found and prevent possible rough handling of the pallet. Avoid seams and spots near the bottom of the pallet or covering shipping labels. Make sure each RFID tag has a unique shipping number so you can identify a specific pallet.

Our RFID pallet for tracking are the most efficient solution for pallet and container management in your warehouse or facility. For pallet and container RFID tracking, RFID tags are placed on pallets and containers as a means of identifying them throughout the manufacturing process or in automated storage and retrieval applications. Typically, smallest RFID pallet tags, which are inconspicuous when placed on containers or pallets, can also be used in harsh environments and environments that are constantly moving.

In the process of identifying containers and pallets with RFID tags, an RFID reader will be used to receive the unique identification number of the pallet or container, as well as certain information about the item in transit. In many RFID systems, an RFID reader sends data to a computer via Wi-Fi or a direct connection, where the data is processed by data acquisition software and stored in a database. Maintaining a complete and accurate database of your pallets and containers using RFID tags and readers will ensure you never lose critical information about your business again.

All RFID tag for pallets are available in a variety of options including shape, color, frequency and memory. We can customize according to your needs

Selection of Short RFID tags for pallets

Let's us know if you didn't find out what you need.

GEN2 UHF High Temperature RFID tags

It can be mounted on any surface and supply long read rangeView Details

GEN2 UHF On Metal RFID tags

GEN2 UHF On Metal RFID tags are ABS anti-metal tags and PCB anti metal tagsView Details

GEN2 UHF RFID laundry tag

There are flexible and elastic silicone RFID Laundry Tags ...View Details

GEN2 UHF Animal RFID tag

GEN2 UHF RFID animal tags help manage and safeguard livestock ...View Details

Rugged RFID tags

EPC GEN2 Rugged RFID tags has been tested in several applications. ....View Details

RFID Windshield tag

The RFID Windshield tag is designed to be attached to optimization. ....View Details

Smallest RFID tags

We developed the mini RFID tag is the world's smallest rfid tag for many applicationsView Details

Request A Quote or Samples