Description

The cylinders are industrial gas companies' key physical returnable assets and are a huge investment.

People in the industry know that reading, writing, and entering gas cylinder data take up much of their workers’ time. On top of this, the process is repeated multiple times during receiving, filling, shipping, and tracking. Moreover, around 5% of manual entries are incorrect.

Ultimately, this lack of up-to-date data results in the inability to easily locate assets and in the lack of readily available information about an asset’s operational status when it is most needed.

Business productivity is invariably tied to how well its key physical assets are being managed. Knowing what cylinders are available, where they are at any given time and what their operational status is, are all critical elements that have a direct impact on the bottom-line.

We provide an efficient Gas Cylinder RFID Tags to keep asset location and status data up-to-date. RFID technology makes the systems of industrial gas companies more efficient by improving the rotation of returnable assets, overcoming a number of transcription errors, and avoiding the loss of cylinders.

The UHF gas cylinder RFID tag has good metal resistance, can realize long-distance reading and writing in metal performance, and can be used indoors and outdoors. It has multi-tag recognition with high-temperature resistance, water resistance, acid and alkali resistance, and impact resistance. The recognition sensitivity is high, the speed is fast, and the ball identification code is available. Mainly used in electronic equipment, asset maintenance, gas cylinders, elevator maintenance, auto parts, high-pressure boilers, high-pressure vessels, high-pressure pipelines, lifting machinery, amusement facilities, and other metal items and special equipment management.

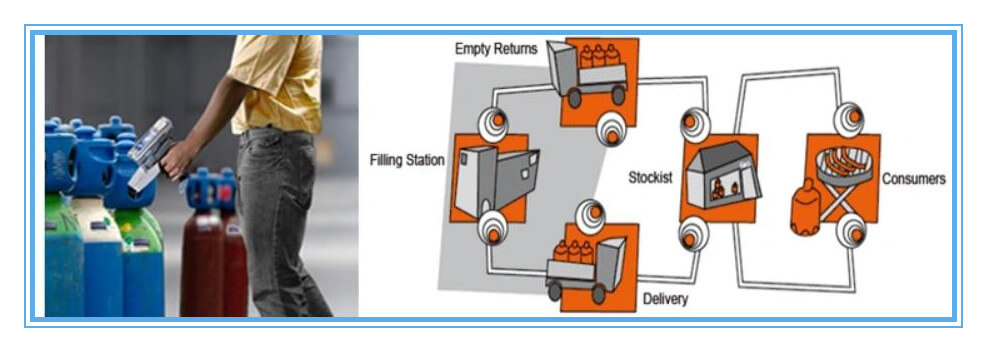

Concept of Tracking Gas Cylinder by Using RFID Technology

As soon as the gas cylinder reaches the warehouse/premises from the Company, these gas cylinders are been attached with RFID tags in batches.

The RFID tagged gas cylinders are scanned with the RFID handheld reader or and taken in the stock record.

To double-check the stock, a long-range RFID reader is installed at the door of the warehouse. Whenever these RFID tagged gas cylinders enter the warehouse, these cylinders are scanned again by the long-range RFID reader and antenna and are cross-checked with the stock taken by the RFID Handheld reader. Any cylinder moving in or out from the warehouse is automatically detected/registered by the long-range RFID reader at the door.

Specification

| Item | Gas cylinder RFID tag |

|---|---|

| Material | ABS+Sponge with glue |

| Dimension | 62*32*8mm or customized |

| Available chip | UHF/HF13.56mhz : I CODE SLIX, FM1108, impinjM4D/M4E/M4QT/M5 |

| Product technology | Logo printing : Digit printing, offset printing and silk printing |

| Number printed will be available ( Serial No & Chip UID) | |

| Collect UID code excel,text file etc. | |

| Chip program/encode will be available as well ( URL ,TEXT ,Number and Vcard) | |

| Customize size and shape , Hole punch etc | |

| Antenna | Copper & etching Aluminum material |

| Operation temperature | (-25℃~+55℃) |

| Store temperature | (-35℃~+75℃) |

| gas cylinder tracking,asset tracking,warehouse,container |