RFID Tire Tag

D.O RFID TAG Manufacturer has been developed the RFID tire Tag for rfid tires tracking.Put rfid chip in tires during the manufacturing process, high temperature resistant, long read distance for tracking and identification tires application.Features

- 0~2m read range when mounted on the tire

- Flexible construction to withstand tire deformation in the total lifetime of the tire

- Mounted on the inner side-wall of the tire

- The factory programmed tag identification number is unique to prevent cloning

Description

RFID Tire tag is being adopted rapidly in a growing number of tire industry processes and will deliver more transparency, fewer rejected tires and production failures and better control of materials.

Major tire producers are investigating new technologies to support their internal production processes and to gather more data per process step for individual tires. Our RFID tire tag has emerged as the answer to the industry's problem. RFID (Radio-frequency identification) is a technology that will rapidly change the tire industry by supporting the improvement of the overall quality of individual tires. RFID tire tag provides benefits such as inventory management and casing tracking that help alleviate costs associated with the RFID technology.

Furthermore, large volumes of data will be gathered to support decisions with better intelligence. RFID Tire tag is the booster for the "Industry 4.0 Development."

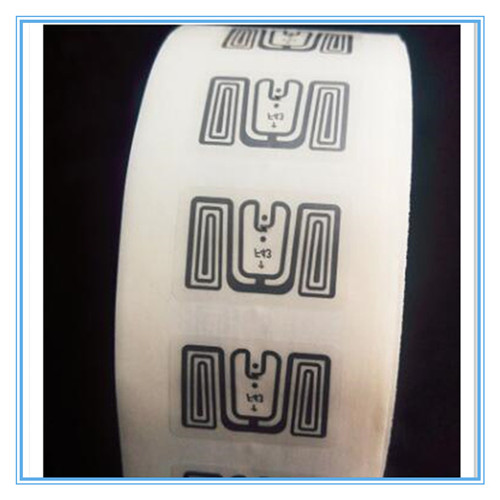

The RFID tire tag with an RFID antenna and RFID chip. This antenna mostly is applied on a carrier such as a PET, polypropylene, paper or, rubber materials. This RFID chip is applied with ultra-high frequency class one Gen2 RFID that has been certified as the world standard for passive (without a battery) RFID tags.

A comprehensive RFID solution always contains the RFID tag, software, and an RFID handheld or stationary RFID reader including antennas. When an RFID tire tag passes the reading field of an antenna, it reads the RFID tag in the tire and sends the unique identification number back to the system. This can be a speedy process with up to 300 of these identifications per second.

In comparison to identification by bar codes, there is a range of benefits. There is no line-of-sight needed between the reader and the tag. Identification can occur in bulk, up to 150 tires in one scan. And the distance from which RFID tire tags can be read is more flexible than for bar codes, from zero up to several feet.

The tire industry recognizes these benefits and several solutions based on RFID technology have been defined in the past few years

The RFID Tyre Patch Vehicle UHF Tag provides a unique identification number that can be tracked to prevent tire theft and cloning, in addition to the conventional asset tracking benefits inherent to RFID. This tag can be embedded in other items. Such as trunk,box,etc,Its advantage is small size,resist at least 200℃,etc.

In 2013, Kumho Tire Co. announced plans to embed a passive RFID tag in all of the 35 million tires it produces in its factories to enable them to be tracked at the factory, through the supply chain, at stores, and by owners. In 2012, Michelin began supplying tires with RFID tags to some London buses. The RFID tire tags are used in conjunction with embedded wireless air pressure sensors. During a tire inspection, a handheld RFID reader reads the number encoded on the RFID tire tag to identify the tire and read the pressure sensor. Finally, the operator utilizes the reader to determine tread depth. The pressure and tread-depth data is linked with the tire’s identification number and sent to a database.

Goodyear and Dunlop have both taken RFID into motorsports.

In Europe, the Dunlop MSA British Touring Car Championship successfully pioneered automatic scanning of tires in the pit lane. In the FIA European Truck Racing Championship, all Goodyear truck race tires are built with RFID tire tags inside. This year, Dunlop introduced RFID technology to the Moto2 and Moto3 classes of the MotoGP motorcycle racing series. These spec-tire race series closely control the number of tires allocated to each team and require that specific construction be used at designated tracks. RFID ensures no tire is missed and the race organizers are provided with an accurate log of each tire’s activity. This is still a relatively simple use of technology. The next stage will be to provide real-time feedback from the tires, passing the data back to monitoring systems using active, rather than passive, RFID chips.DO RFID TAG manufacturer produced the RFID tire tags to help manufacturers to identify, track, and manage tires all through their production and distribution processes, increasing read rates, cutting labor costs, reducing scrap and rework.

A flexible material designed with a very aggressive and tacky-rubber based adhesive makes it an ideal construction for tire (tread or sidewall) tracking applications. The addition of a thermal transfer printable top layer and embedded RFID inlay makes for a perfect inventory control tag. The tire patches RFID tag with a UHF RFID chip to be installed tires after manufacture. Each patch RFID tag contains a factory programmed EPCglobal unique part number which can be tracked to prevent truck tire theft and cloning with RFID technology.

Our RFID tire tag provides excellent performance when an integral part of tire retread operations, fleet management, or tire warranty/recall processes. It allows discrete long lasting RFID management and tracking of tires that don’t have RFID capabilities.

RFID tire Tag designed for application to sidewall after manufacture

Aftermarket RFID tire tracking, Prevent tire theft through rapid RFID tracking of all tires

RFID tire tags are rubber based and have a flexible design to stand up to regular tire deformation and wear and tear. Tire tag installation procedures are similar to applying a heavy-duty tire patch to the inside of a tire. Users apply these labels directly onto the tire, tire tread, micro-vented tires or mold-release treated tires. Thoroughly clean, smooth, and prepare inside tire surface, use the vulcanizing cement to pressure and allow cement time to cure then seal the patch by a sealer. 14-110 hours for curing time.We have another metal spring tire tag embeddable into the tire.

Please see more details about our RFID tire tags.

Specification

| Material | Metal Spring or rubber |

|---|---|

| Dimensions | 90x1mm |

| 85*38*2.5mm or customize | |

| Working temperature | -40°C;C~230°C |

| Protocol | EPC C1G2 (ISO18000-6C) |

| Frequency | 860~960MHz |

| Chip | Alien Higgs-3 |

| EPC memory | 96 bits, max 480 bits |

| User memory | 512 bits |

| Read range | 0.5~1.5m(depend on the reader power) |

| ROHS compliant | Yes |

| Data storage | >10 years |

| Re-write | 100,000 times |

| Fixture | Embedded or mounted inner side of the tire |

Primary Applications:

- Parking

- Vehicle Management

- Vehicle Charge

- Auto Glass Retail Management

- Toll collection and contactless payment

Why our RFID Tire tag fit tire manufacturer?

RFID tire tag is proving invaluable in helping manufacturers identify, track, and manage tires and other assets all through their production and distribution processes…

It’s a key component in increasing productivity, reducing waste and bringing down costs.

Total automation saves on labor

The RFID chip-held data is accessed or managed automatically – no need for hand scanning or any kind of human intervention.

Real-time tracking.

Assets can be tracked inside the tire plant, reducing the time required to locate materials used in the production process.

High temperature resistant

Raw materials like sulfur, rubber, and carbon black are mixed to form the rubber compound let the RFID tire tag can be resistant to the high temperature while production.

Smarter design

At the earliest opportunity designed the rubber RFID Tire tag patch what it can be attached on the tire. like the tire, in some cases using the same tools. Aesthetics can also be improved, as the tag can be invisible -embedded in or integrated into the product design. This is our metal spring tire tag.

Real-time retail advantages

RFID tags offer exceptional benefits in inventory tracking. Knowing where everything is, what it is, where it’s been and its current status in an instant delivers powerful management and cost control benefits