RFID Paper is a lightweight and cost-effective RFID label solution widely used for item identification and tracking. It integrates an RFID chip and antenna into a paper-based substrate, making it ideal for applications such as retail labeling, logistics tracking, document management, and library systems. RFID paper tags support fast, contactless reading without line-of-sight, enabling bulk scanning and higher efficiency compared with traditional barcodes. They are easy to print, encode, and apply, offering excellent compatibility with automated systems while keeping deployment costs low.

Description

RFID paper is the best solution for printing production for the rapid entry to the IoT market.

The HF, NFC, or UHF enabled RFID paper has been used predominantly to print RFID-based paper packages, documents. RFID Paper can be printed via printers to produce any other RFID products.

In the past, we use RFID inlay to make RFID tags, NFC business cards, cloth hangtags, or RFID paper cards.

But now we print the RFID antenna and RFID chip on the paper sheet directly. for an easy step, you just put paper in the printer tray and send artwork to print, then cut, punch and your RFID products are ready, also you can easily encode your website or anything to an RFID chip with just a couple of clicks.

We created a simple paper solution with RFID chips and antennas built into ready-to-print sheets Instead of the traditional format of RFID tags. We hope to make RFID technologies as available and affordable as any usual sheet-to-sheet printing.

The RFID paper could be read by a standard reader, and flat surface RFID paper able to pass the tracks inside the printer. Also, the RFID paper is able to withstand heating and cooling during the printing process. The RFID sheets should be tolerant of the impact of logistics and storage, as well as able to survive cutting, embossing, punching, and folding.

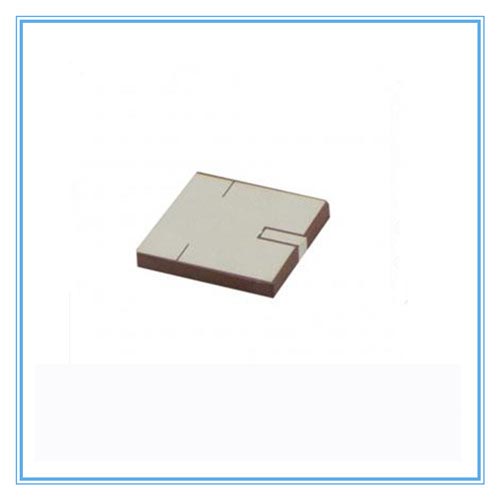

RFID Paper is a smart paper with various RFID chips, It allows for producing a wide range of contactless paper cards and RFID tags, NFC cards, RFID magazines, or security documents. they are ideal for low-cost, high-volume applications such as public transport, loyalty cards, event ticketing. Supports ISO/IEC 14443 A 1-3 and NFC forum tag type 2 compliant.

Our RFID PAPER is RoHS certified material integrated with RFID chips and antennas. The RFID consists of 13.56Mhz (Mifare 1k, Mifare ultralight),NFC (NTAG213,NTG215),UHF.

13.56Mhz RFID paper usually uses for transport paper tickets, hotel cards, parking tickets, loyalty cards.

NFC paper usually uses for advertising and brand protection hangtag, NFC business cards.

UHF paper usually uses for paper inventory hang tags, traceability labels.

Printable RFID paper creates a game-changing shift in the market. We aim at making NXP technologies as available and affordable as a usual sheet to sheet printing that would increase customer satisfaction and quality of service in all areas of business.

Primary Applications:

- Transport tickets

- Access control cards

- Parking tickets

- Hang tags

- Event tickets

- Corporate NFC business cards

- Passport

- security document

Choosing suitable RFID tags

What Is RFID Paper?

RFID Paper refers to paper-based labels or sheets embedded with an RFID inlay, which consists of a microchip and an antenna. From the outside, it looks like ordinary label paper. Inside, it behaves like a wireless data carrier.

RFID paper is commonly used to produce:

- RFID paper labels

- RFID smart stickers

- RFID printable labels

- RFID tickets and tags

These labels can be printed, encoded, and applied using standard label printers and applicators, making them ideal for high-volume, cost-sensitive applications.

Most RFID paper products operate in:

- UHF (860–960 MHz) – long-range, bulk reading

- HF (13.56 MHz) – short-range, NFC-compatible

They support protocols such as EPC Class 1 Gen 2 and ISO standards, ensuring compatibility with mainstream RFID systems.

How RFID Paper Works (Simple but Powerful)

At its core, RFID paper works through wireless radio communication between a reader and the embedded tag.

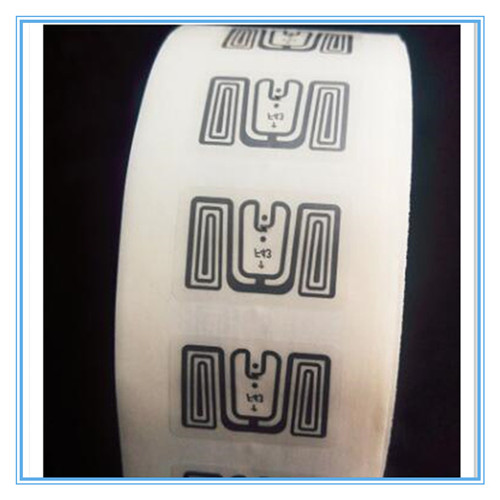

1. The RFID Inlay

Inside the paper label is an RFID inlay, which includes:

- An RFID chip (stores data)

- A thin aluminum or copper antenna (transmits data)

The inlay is laminated between layers of paper or paper + adhesive.

2. Energy Harvesting

RFID paper labels are typically passive, meaning:

- No battery

- Powered by the electromagnetic field emitted by an RFID reader

When the reader sends out radio waves, the antenna captures energy and activates the chip.

3. Data Transmission

Once powered, the chip:

- Sends its unique ID (EPC)

- Can transmit stored data

- Can accept new data if writable

This happens in milliseconds, without physical contact or line of sight.

4. System Integration

The reader sends data to:

- Warehouse Management Systems (WMS)

- ERP systems

- POS systems

- IoT platforms

This creates a real-time digital record of physical items.

The Real Problems RFID Paper Solves

Pain Point 1: Manual Scanning Is Slow and Error-Prone

Barcodes require:

- Line-of-sight

- One-by-one scanning

- Human involvement

This leads to:

- Labor costs

- Missed scans

- Inaccurate inventory

RFID paper solves this by enabling:

- Bulk reading (hundreds of items at once)

- No line-of-sight requirement

- Automated scanning at gates, shelves, or conveyors

Result: Inventory speed increases dramatically, accuracy exceeds 95%.

Pain Point 2: Inventory Inaccuracy and Stock Blindness

Many businesses don’t actually know:

- What they have

- Where it is

- Whether it’s lost, sold, or misplaced

RFID paper creates item-level visibility, allowing:

- Real-time inventory updates

- Automatic reconciliation

- Continuous cycle counting

This eliminates blind spots that cause overstocking, stockouts, and lost sales.

Pain Point 3: Labels That Don’t Last

Traditional paper labels:

- Tear easily

- Smudge or fade

- Fail in humidity or handling

RFID paper labels can be:

- Coated or laminated

- Designed for short-to-medium lifecycle use

- Optimized for logistics, retail, or ticketing

They balance cost efficiency with functional durability.

Pain Point 4: Lack of Traceability

In many industries, once a product leaves a process step, it becomes invisible.

RFID paper enables:

- End-to-end traceability

- Time-stamped movement tracking

- Batch and item history recording

This is critical in logistics, pharmaceuticals, food, and manufacturing.

How RFID Paper Solves These Problems (Step by Step)

Step 1: Unique Identification at Item Level

Each RFID paper label carries a unique digital identity, not just a printed code.

This means:

- No duplication

- No manual matching

- No confusion between identical items

Step 2: Automated Data Capture

Fixed readers or handheld readers capture data automatically when items pass through a read zone.

No stopping.

No scanning guns.

No paperwork.

Step 3: Real-Time System Updates

As soon as a tag is read:

- Inventory updates

- Location is recorded

- Status changes are logged

This creates live operational intelligence.

Step 4: Data-Driven Decisions

With clean, continuous data, businesses can:

- Forecast demand

- Optimize replenishment

- Reduce shrinkage

- Improve fulfillment speed

RFID paper becomes a data engine, not just a label.

Key Applications of RFID Paper

Retail and Apparel

RFID paper labels are widely used for:

- Item-level inventory

- Shelf accuracy

- Omnichannel fulfillment

- Loss prevention

Retailers using RFID consistently report:

- Higher sales

- Fewer out-of-stocks

- Faster store operations

Logistics and Warehousing

RFID paper labels enable:

- Pallet and carton tracking

- Automated receiving and shipping

- Faster audits

- Reduced labor dependency

They integrate seamlessly with conveyor and gate systems.

Ticketing and Events

RFID paper tickets are used for:

- Event access control

- Transportation tickets

- Visitor management

They offer:

- Anti-counterfeiting

- Fast throughput

- Better user experience

Healthcare and Pharmaceuticals

RFID paper supports:

- Medication tracking

- Sample identification

- Medical waste tracking

- Compliance reporting

Accuracy here isn’t optional—it’s essential.

Manufacturing and Work-In-Process (WIP)

RFID paper labels track:

- Components

- Assemblies

- Process stages

This improves production visibility and quality control.

RFID Paper vs Traditional Barcode Paper

| Feature | Barcode Paper | RFID Paper |

|---|---|---|

| Line of sight required | Yes | No |

| Bulk reading | No | Yes |

| Automation level | Low | High |

| Data capacity | Very limited | Expandable |

| Error rate | Higher | Lower |

| Labor dependency | High | Low |

RFID paper doesn’t replace barcodes—it outgrows them.

Cost Considerations and ROI

RFID paper labels cost more than standard paper labels, but:

- Labor savings offset label cost

- Inventory accuracy reduces losses

- Automation increases throughput

- Data quality improves decision-making

For most operations, ROI is achieved faster than expected, especially at scale.

Choosing the Right RFID Paper

Key factors to consider:

- Frequency (UHF vs HF)

- Chip sensitivity and memory

- Printer compatibility

- Adhesive type

- Environmental conditions

- Volume and consistency

Working with experienced manufacturers ensures stable performance and predictable results.

Why RFID Paper Is a Strategic Tool, Not Just a Label

RFID paper transforms physical objects into digital participants in your system. Each label becomes a node in your IoT network, feeding data into analytics, automation, and optimization engines.

It’s not about tags.

It’s about visibility, speed, and control.

Conclusion

RFID Paper is one of the most practical and scalable RFID products available today. It combines the low cost and flexibility of paper with the intelligence and automation of RFID technology.

By solving critical pain points—manual scanning, inventory inaccuracy, traceability gaps, and labor inefficiency—RFID paper enables businesses to move faster, see clearer, and operate smarter.

For organizations serious about automation, digital transformation, and operational excellence, RFID paper isn’t a future upgrade.