UHF RFID anti metal tag

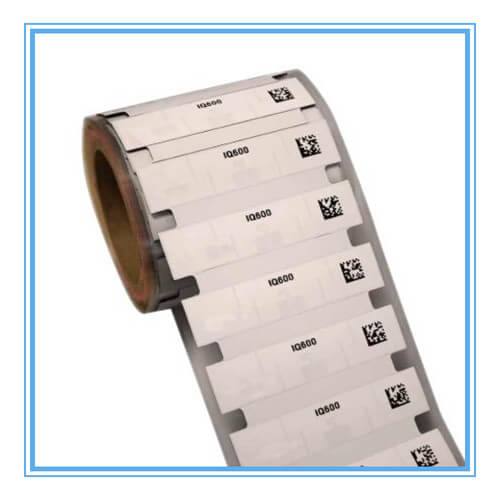

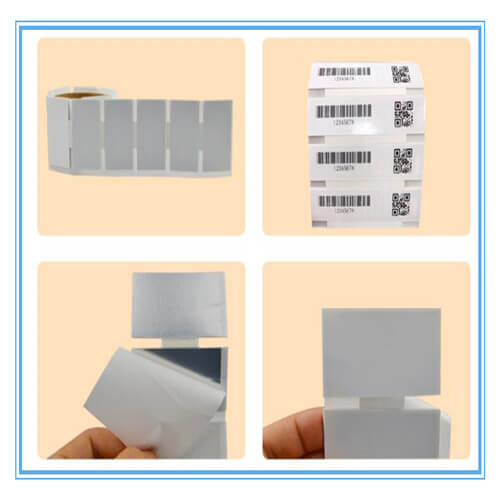

DO RFID tag manufacturer produced the Printable RAIN UHF RFID anti-metal tag, This UHF anti-metal tag is made of soft material and printable by RFID printers. and PCB anti metal tags. Contact a expert for the right tags.Features

- EPC C1 GEN2(ISO 18000-6C) Protocol

- Can be mounted on metal surface and supply long read range

- Flexable for conductive surface

- Printable by zabra printer

Description

RFID application get more and more popular, Many RFID applications have different requirements – from reading distance to dimension, printing, and encoding, etc.

There is a big problem that RFID tag will not work on the metal project. When an RFID reader scans an RFID tag, it sends a radio-frequency electromagnetic field that powers the tag (passive tags) and allows the RFID reader to communicate with the tag. The problem arises when the RFID tag is fixed to a conductive surface, such as metal. The conductive surface alters the electromagnetic field created by the RFID reader so that the RFID tag isn't able to use the electromagnetic field to communicate with the reader.

In order to solve this problem, we developed various Anti-Metal RFID Tags.Anti-metal tags are specialized RFID tags that can be read from conductive surfaces, such as metal (something that regular RFID tags can't do).

DO RFID tag manufacturer produced the Printable RAIN UHF RFID anti-metal tag, This UHF anti-metal tag is made of soft material and printable by RFID printers. It’s industry’s best performance and excellent read ranges regardless of the surface metal, plastic, even wood. This UHF RFID anti-metal tag with a small footprint and low profile and easily fits where is too small and obtrusive or adhere to curved surfaces.

Printable RAIN UHF RFID anti-metal tag is a specially designed for a thermal printer and easy to be installed on a metallic surface, liquid environment. The UHF anti-metal tag with popular RFID chip Impinj Monza R6-P that operates properly in optional ultra-high frequencies ( 866MHz – 868MHz (ETSI); 902MHz – 928MHz (FCC) ).it with Memory: EPC – 128 (96) bits; User – 32 (64) bits; Unique TID – 48 bits. User can be encoded by the UHF RFID reader writer or we help encode during we produce it. The Reading Range with long range RFID readers Up to 6m, The read range is up to 3 meters if use the RFID handheld reader. this broad range of RAIN UHF RFID anti-metal tag comes with various sizes for client’s optional. Please kindly noted, the different sizes with the different read distance, please check with our RFID expert before purchase it. We have existing imensions: 40 x 40 x 1.1mm, 55 x 12.5 x 1.3mm, 96 x 12.5 x 1.3mm, 96 x 24 x 1.3mm, absolutely , DO RFID TAG manufacturer can custom any size as your request.

Flexible printable UHF RFID anti-metal tag is an updated concept for the UHF thin on metal as a fantastic solution to make it possible to implement RFID applications for industrial automation and for supply chain management as well as inventory tracking purposes, such as: tracking IT Assets, Office, Hospital and Laboratory asset management. The simple RAIN RFID On-Metal Tags offer a quick and cost-effective tagging function after attached on a metallic surface. With printable, stick flexibility, cost-effective and efficient, global frequency, good performance.

Primary Applications:

- tracking IT Assets

- Production line high temperature metal tray management

- Warehouse Rack Management

- University logistics asset management

- Special vehicle management

- IT, Office, Hospital and Laboratory Asset Tracking

- Weapons, Pipes, and Road Signs

What Is a UHF RFID Anti Metal Tag?

A UHF RFID anti metal tag is a specialized RFID tag designed to operate directly on metal surfaces without performance degradation. Unlike standard UHF RFID tags, which rely on free-space electromagnetic fields, anti metal tags incorporate shielding, isolation layers, or special antenna structures that prevent metal from detuning the RFID signal.

Operating in the UHF frequency range (860–960 MHz), these tags support long reading distances, fast identification, and bulk scanning, making them ideal for industrial-scale asset tracking and logistics applications.

In simple terms, an anti metal tag allows UHF RFID technology to work in places where metal would normally make RFID impossible.

Why Standard UHF RFID Tags Fail on Metal

Metal reflects and absorbs radio frequency signals. When a standard UHF RFID tag is placed on a metal surface, several problems occur:

- Antenna detuning, causing signal mismatch

- Severe reduction in reading distance

- Unstable or inconsistent reads

- Complete tag failure in some cases

These issues are unacceptable in professional environments where accurate and repeatable identification is required. UHF RFID anti metal tags are engineered specifically to overcome these challenges.

How UHF RFID Anti Metal Tags Work

The key to anti metal performance lies in antenna design and material structure.

Most UHF RFID anti metal tags use one or more of the following technologies:

- Isolation layers between the antenna and metal surface

- Ferrite or dielectric materials to redirect RF energy

- Special antenna tuning optimized for metal mounting

- Encapsulated housing to protect performance stability

By controlling how RF energy interacts with metal, the tag maintains proper impedance matching and consistent communication with UHF RFID readers.

For procurement teams, this means predictable performance—even when tags are mounted on steel racks, machinery, tools, or containers.

Key Features of UHF RFID Anti Metal Tags

Stable Reading Performance on Metal

Anti metal tags provide reliable reading distances, typically ranging from 1 meter to over 10 meters, depending on tag size, reader power, and installation method.

Industrial-Grade Durability

These tags are commonly designed for harsh environments, offering resistance to:

- Dust and moisture

- Vibration and mechanical impact

- Chemicals and oils

- Temperature fluctuations

Long Service Life

UHF RFID anti metal tags are built for long-term use, often matching the lifecycle of the asset they are attached to.

Multiple Mounting Options

Common mounting methods include:

- Screws or rivets

- Industrial adhesives

- Welding or embedding

- Magnetic or clip-based solutions

Common Applications of UHF RFID Anti Metal Tags

UHF RFID anti metal tags are widely used across industries where metal assets must be tracked accurately.

Manufacturing and Industrial Equipment

Tracking tools, molds, fixtures, and machines improves asset utilization and maintenance planning.

Warehousing and Logistics

Metal shelves, pallets, containers, and cages can be identified and tracked in real time.

IT and Data Center Asset Management

Servers, cabinets, and network equipment are often metallic and require anti metal RFID solutions.

Oil, Gas, and Energy

Harsh environments and metal infrastructure make anti metal tags essential for compliance and safety tracking.

Automotive and Aerospace

Parts tracking, work-in-process management, and returnable transport items rely heavily on metal-mounted RFID tags.

UHF RFID Anti Metal Tag vs Standard RFID Tag

From a purchasing perspective, the difference is not just technical—it is operational.

Standard UHF RFID tags may appear cheaper initially, but they often lead to:

- Installation failures

- Increased labor cost

- Inaccurate data

- System redesign

UHF RFID anti metal tags cost more per unit, but they reduce total project cost by ensuring the system works as intended from day one.

Important Specifications Buyers Should Evaluate

When sourcing UHF RFID anti metal tags, B2B buyers should focus on the following parameters:

- Operating frequency (860–960 MHz)

- Chip type and memory capacity

- Reading distance on metal

- Mounting method and surface compatibility

- IP rating and environmental resistance

- Temperature tolerance

Requesting real-world test data rather than theoretical values is strongly recommended during procurement.

Customization Options for OEM and Large Projects

Professional manufacturers offer customization services to match project-specific requirements, such as:

- Size and form factor

- Housing material (ABS, PPS, ceramic, PCB-based)

- Logo or laser marking

- Memory configuration

- Mounting hole positions

Procurement tip:

If your project involves long-term deployment or brand integration, requesting OEM customization early can significantly reduce future redesign costs.

Integration with UHF RFID Systems

UHF RFID anti metal tags are designed to work with standard UHF RFID readers and middleware. They support bulk reading, fast inventory cycles, and integration with ERP, WMS, and asset management platforms.

Proper tag selection ensures:

- Higher read rates

- Fewer missed scans

- Cleaner data for analytics

Quality Control and Compliance

For global deployments, compliance and quality consistency are non-negotiable. Reliable UHF RFID anti metal tags are manufactured under ISO quality systems and comply with regional RF regulations.

Consistent batch performance is especially critical for large-scale installations.

Procurement Considerations for Bulk Buyers

When purchasing UHF RFID anti metal tags in volume, buyers should consider more than unit price.

Key questions to ask suppliers include:

- Can you provide samples for metal surface testing?

- How consistent is reading performance across batches?

- What is the production capacity and lead time?

- Do you support long-term supply for the same model?

Procurement hint:

Choosing a supplier with strong engineering support often saves more money than negotiating the lowest initial price.

Why Choose a Professional UHF RFID Anti Metal Tag Manufacturer?

A qualified manufacturer does more than supply tags. They help:

- Select the right tag model

- Optimize mounting and orientation

- Reduce project risk

- Support system integration

For system integrators and enterprise buyers, this partnership approach is crucial.

Future Trends in Anti Metal RFID Technology

As asset tracking becomes more digitalized, UHF RFID anti metal tags continue to evolve with:

- Smaller form factors

- Higher sensitivity chips

- Wider temperature tolerance

- Integration with sensor technologies

These advancements will further expand RFID usage in metal-heavy industries.

Conclusion

The UHF RFID anti metal tag is a specialized but essential product for modern industrial RFID systems. By overcoming the challenges posed by metal surfaces, it enables reliable identification, long-range reading, and scalable asset tracking.

For B2B buyers, selecting the right UHF RFID anti metal tag is not just a technical choice—it is a strategic procurement decision that affects system performance, operational efficiency, and long-term cost.

If your project involves metal assets, heavy equipment, or industrial environments, investing in the right anti metal RFID tag from a reliable manufacturer is the most direct path to a stable and successful RFID deployment.

Ready to Source UHF RFID Anti Metal Tags?

If you are planning a bulk purchase or OEM project, request samples for real metal testing, confirm customization options early, and work with a supplier who understands industrial RFID—not just tags.