In modern operations, physical assets move faster than spreadsheets can keep up with. Pallets circulate between warehouses, cartons pass through multiple logistics nodes, machines change locations on factory floors, and valuable equipment quietly disappears into operational blind spots. Traditional labels fall off, barcodes fade, and manual tracking becomes a game of educated guessing.

This is exactly where the RFID disc token tag, also known as an RFID coin tag, proves its value.

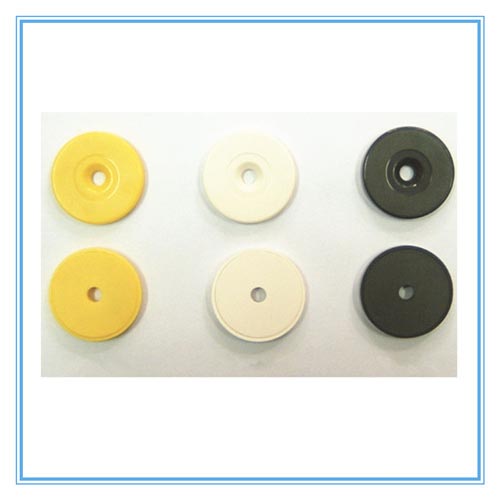

Compact, rugged, waterproof, and cost-effective, RFID disc token tags are designed for warehouse management, asset tracking, logistics control, and industrial automation. Their round, coin-like form factor allows easy installation on pallets, cartons, containers, machines, and even metal surfaces when combined with anti-metal layers.

This article offers a comprehensive, SEO-friendly deep dive into RFID disc token tags, covering features, specifications, working principles, applications, and the operational pain points they solve across industries.

What Is an RFID Disc Token Tag?

An RFID disc token tag is a compact RFID transponder housed in a round ABS or PVC enclosure. Because of its shape, it is often called an RFID coin tag, RFID token, or RFID disc tag.

Unlike flexible RFID labels, RFID disc token tags are designed for durability and reuse. They resist water, shock, and environmental stress, making them suitable for both indoor and outdoor applications.

Each RFID disc token tag contains:

-

An RFID chip

-

An embedded antenna

-

A protective hard shell (ABS or PVC)

Once attached to an object, the tag provides a unique digital identity that can be read wirelessly by RFID readers, without line of sight.

Why RFID Disc Token Tags Matter in Modern Management Systems

Warehouse and asset management increasingly demand accuracy, automation, and durability. RFID disc token tags address several long-standing problems:

-

Paper labels deteriorate in harsh environments

-

Barcodes require manual, line-of-sight scanning

-

Adhesive labels peel off pallets and containers

-

Manual asset tracking leads to data gaps and losses

RFID disc token tags replace fragile identifiers with robust, machine-readable markers that work consistently over time.

Think of them as digital nameplates for physical objects—small, silent, and extremely reliable.

Key Features of RFID Disc Token Tags

1. Compact and Versatile Design

The disc shape allows installation on:

-

Wooden or plastic pallets

-

Cartons and reusable containers

-

Industrial machines and tools

-

Public infrastructure assets

Their low profile minimizes interference with handling and stacking.

2. Multiple Size Options

RFID disc token tags are available in various diameters, allowing optimization for read range, available space, and cost control.

Common sizes include:

-

20 mm

-

27 mm

-

30 mm

-

50 mm

-

Custom sizes upon request

This flexibility makes them suitable for both small items and large assets.

3. Durable ABS or PVC Materials

The housing material plays a critical role in tag longevity:

-

ABS offers excellent impact resistance

-

PVC provides smooth surfaces and cost efficiency

Both materials protect the internal RFID components from mechanical stress and environmental exposure.

4. Waterproof and Shock-Proof Performance

RFID disc token tags are designed for real-world conditions:

-

Waterproof construction

-

Shock-proof housing

-

Resistant to dust and moisture

This makes them suitable for warehouses, outdoor yards, factory floors, and logistics hubs where conditions are far from gentle.

5. Wide Frequency Support

One of the major advantages of RFID disc token tags is multi-frequency compatibility:

-

LF (125 kHz) – short range, stable in metal or liquid environments

-

HF (13.56 MHz) – NFC compatibility, medium range

-

UHF (860–960 MHz) – long range, bulk reading capability

This allows system designers to choose the optimal frequency for each application.

6. Economical Cost for Large-Scale Deployment

RFID disc token tags strike a balance between durability and affordability. Compared with active RFID tags, they:

-

Require no battery

-

Have long service life

-

Offer low cost per unit at scale

This makes them ideal for large-volume deployments in logistics and warehouse environments.

RFID Disc Token Tag Technical Specifications

Below is a structured overview of the core specifications:

Material

-

ABS

-

PVC

Dimensions

-

Diameter: 20 mm / 27 mm / 30 mm / 50 mm

-

Custom sizes available

Thickness

-

2 mm to 8 mm

Color

-

Default: White or Black

-

Custom colors available

Operating Temperature

-

-20°C to +50°C

Operating Frequency

-

LF (125 kHz)

-

HF (13.56 MHz)

-

UHF (860–960 MHz)

Features

-

Waterproof

-

Shock-proof

Craft and Customization

-

Silk-screen printed logo

-

Laser engraved logo or serial number

-

Sticker printing

-

Optional anti-metal layer

Humidity Resistance

-

Suitable for indoor and outdoor use

Operating Humidity

-

40% to 80% RH

How RFID Disc Token Tags Work

RFID disc token tags are typically passive RFID devices, meaning they do not contain a battery.

Here’s the simplified process:

-

An RFID reader emits radio frequency signals

-

The RFID disc token tag receives energy from the signal

-

The chip activates and transmits its stored ID data

-

The reader captures and processes the information

This interaction happens in milliseconds, even when multiple tags are present.

In UHF systems, hundreds of RFID disc token tags can be read simultaneously, making them ideal for bulk operations.

Installation Methods for RFID Disc Token Tags

RFID disc token tags can be installed using several methods, depending on the asset and environment:

-

Adhesive bonding

-

Screws or rivets

-

Embedding into pallets or plastic parts

-

Mounting with anti-metal backing for metal surfaces

Their rigid structure ensures they remain firmly attached over long service cycles.

Core Applications of RFID Disc Token Tags

1. Warehouse Management

In warehouse environments, RFID disc token tags are commonly installed on:

-

Pallets

-

Reusable bins

-

Storage racks

They enable:

-

Automated inventory counts

-

Real-time pallet tracking

-

Faster inbound and outbound verification

-

Reduced manual scanning labor

Warehouse managers gain visibility without interrupting operations.

2. Logistics Management

RFID disc token tags streamline logistics by:

-

Tracking cartons across distribution centers

-

Verifying shipments automatically

-

Reducing misplacement and loss

-

Improving traceability across transport stages

With UHF RFID, entire truckloads can be scanned at dock doors in seconds.

3. Inventory Management

Inventory accuracy improves dramatically when each asset carries a unique RFID identity.

RFID disc token tags support:

-

Item-level tracking

-

Location monitoring

-

Cycle counting automation

-

Audit accuracy above 95%

This is especially valuable for high-turnover or reusable assets.

4. Industrial Automation

In automated production lines, RFID disc token tags are used to:

-

Identify workpieces

-

Control process routing

-

Trigger machine operations

-

Track production history

Their shock-proof design ensures reliability even in high-vibration environments.

5. Patrolling Management

In security and facility management, RFID disc token tags are installed at fixed checkpoints.

They enable:

-

Digital patrol verification

-

Time-stamped records

-

Reduced paperwork

-

Improved accountability

LF and HF RFID disc token tags are particularly common in patrol systems.

6. Casino Tokens

RFID disc token tags are widely used in casino chips and tokens.

Benefits include:

-

Anti-counterfeiting

-

Real-time tracking

-

Automated counting

-

Enhanced security

The coin-shaped form factor is naturally suited for this application.

7. Public Transportation

In public transport systems, RFID disc token tags are used for:

-

Access control

-

Ticketing systems

-

Asset identification

HF (13.56 MHz) RFID disc token tags integrate smoothly with NFC-based infrastructure.

Solving Industry Pain Points with RFID Disc Token Tags

Loss and Misplacement of Assets

Without tracking, pallets and tools quietly disappear. RFID disc token tags provide continuous visibility and accountability.

Manual Data Entry Errors

Automated RFID reading eliminates human error and reduces administrative workload.

Harsh Environmental Conditions

Paper labels fail in moisture and impact environments. RFID disc token tags are built to survive them.

Inefficient Inventory Audits

RFID enables fast cycle counts without halting operations.

Limited Traceability

RFID disc token tags provide historical movement data, supporting audits and optimization.

LF vs HF vs UHF RFID Disc Token Tags

Each frequency serves different needs:

-

LF (125 kHz)

Best for short-range, stable reading near metal or liquids -

HF (13.56 MHz)

Ideal for NFC, access control, and token systems -

UHF (860–960 MHz)

Best for long-range, bulk reading in warehouses and logistics

Choosing the right frequency is key to system performance.

Customization Options

RFID disc token tags can be customized to match operational and branding needs:

-

Logo printing or engraving

-

Unique serial numbers

-

Anti-metal layers

-

Custom colors and sizes

-

Encoding and data initialization

Customization transforms a generic tag into a branded, system-ready component.

Future Outlook for RFID Disc Token Tags

As automation expands, RFID disc token tags will continue to replace manual identifiers. Their low cost, durability, and compatibility with modern systems position them as a foundational technology in:

-

Smart warehouses

-

Industry 4.0 factories

-

Intelligent logistics networks

-

Urban infrastructure systems

Small in size, large in impact.

Conclusion

The RFID disc token tag is a practical, rugged, and economical solution for asset identification in demanding environments. With waterproof ABS or PVC housing, multiple frequency options, and flexible customization, it meets the needs of warehouse management, logistics, industrial automation, and beyond.

In a world where physical assets must speak digitally, RFID disc token tags give them a clear, reliable voice—round, silent, and remarkably efficient.