Warehousing has traditionally been a labor-intensive, error-prone sector. Manual inventory checks, misplaced items, and slow stock audits result in operational inefficiency and increased costs. Modern supply chains require real-time visibility, accurate stock management, and automated operations.

RFID (Radio Frequency Identification) technology has emerged as a game-changer for warehouse management. By enabling automatic identification, tracking, and data collection, RFID systems allow warehouses to optimize inventory control, reduce errors, and improve efficiency.

This article provides a comprehensive SEO guide on RFID applications in warehouse inventory tracking, covering system components, working principles, types of RFID, practical applications, benefits, challenges, and future trends.

1. What Is RFID in Warehouse Inventory Management?

RFID is a wireless identification technology that uses radio frequency signals to automatically identify and track tags attached to objects. In warehouses, RFID systems are used to:

-

Monitor stock movement

-

Track inventory levels

-

Reduce manual labor

-

Enhance accuracy and traceability

Unlike barcodes, RFID does not require line-of-sight scanning, allowing rapid and simultaneous reading of multiple items, even when stacked or stored in bins.

1.1 Components of an RFID Warehouse System

A typical RFID warehouse inventory system consists of:

| Component | Function |

|---|---|

| RFID Tags | Attached to items, pallets, or containers; store unique identifiers and optionally item data |

| RFID Readers | Devices that communicate with tags to capture data |

| Antennas | Facilitate wireless communication between tags and readers |

| Middleware / Software | Processes and manages data, integrates with WMS (Warehouse Management System) |

| Network Infrastructure | Connects readers and software for real-time data access |

| Database | Stores inventory records, logs, and historical data |

Advanced systems may also integrate mobile RFID readers, handheld devices, and IoT platforms for enhanced flexibility.

1.2 Types of RFID Used in Warehousing

RFID tags vary by frequency, read range, and power source. Warehouse systems commonly use:

1.2.1 Low-Frequency (LF) RFID

-

125–134 kHz

-

Short read range (<0.5 m)

-

Rarely used in large warehouses due to limited distance

1.2.2 High-Frequency (HF) RFID / NFC

-

13.56 MHz

-

Read range: 10–30 cm

-

Used for asset-level tracking or pallet-level verification

1.2.3 Ultra High-Frequency (UHF) RFID

-

860–960 MHz

-

Long read range: 3–10 meters or more

-

Ideal for item, carton, and pallet tracking in high-volume warehouses

1.2.4 Active RFID

-

Battery-powered tags

-

Read range: 30–100 meters

-

Suitable for large warehouses, cold storage, and heavy equipment tracking

1.2.5 Semi-Passive RFID

-

Battery-assisted but reader-activated

-

Longer range than passive tags

-

Used for temperature-sensitive or high-value goods

![]()

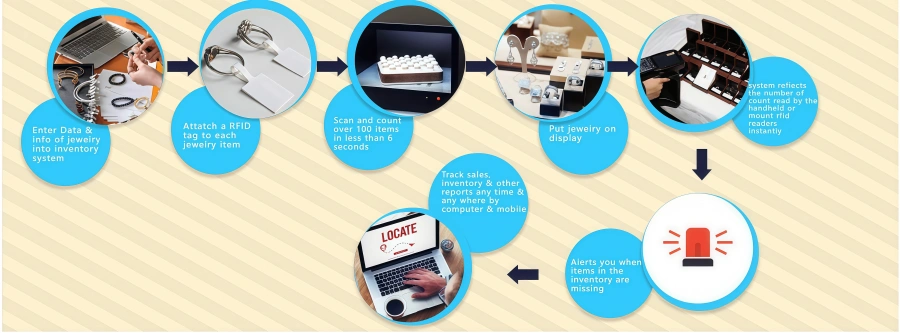

2. How RFID Warehouse Inventory Tracking Works

RFID warehouse systems typically follow this workflow:

-

Tagging: Each item, carton, or pallet is labeled with an RFID tag.

-

Reading: RFID readers scan tags automatically as items enter or leave storage areas.

-

Data Processing: Middleware records item ID, quantity, location, and timestamp.

-

Inventory Update: WMS updates inventory levels in real-time.

-

Alerts and Reporting: Systems generate alerts for low stock, misplaced items, or discrepancies.

With multiple readers, warehouses can achieve continuous real-time visibility of inventory throughout the facility.

3. Applications of RFID in Warehouse Inventory Management

3.1 Item-Level Inventory Tracking

-

Tags on individual products allow precise stock monitoring

-

Enables automated stocktaking and reduces human error

-

Ideal for high-value or serialized items, electronics, or pharmaceuticals

3.2 Pallet and Carton Tracking

-

RFID tags on pallets or cartons simplify bulk inventory management

-

Improves efficiency in receiving, storage, and shipping

-

Supports FIFO (First In, First Out) and FEFO (First Expiry, First Out) inventory rotation

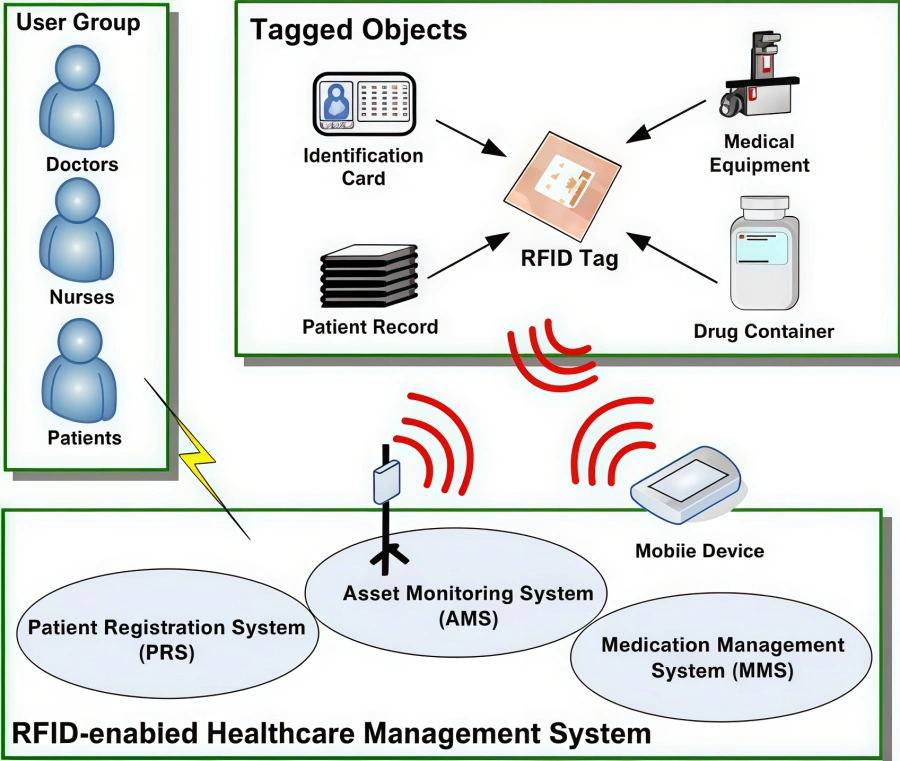

3.3 Asset Management

-

Tracks equipment, tools, and reusable containers

-

Reduces loss or misplacement

-

Integrates with maintenance schedules for industrial assets

3.4 Cold Storage and Temperature-Controlled Warehouses

-

RFID tags with temperature sensors monitor perishable items

-

Alerts for temperature deviations prevent spoilage

-

Ensures regulatory compliance for pharmaceuticals and food

3.5 Real-Time Inventory Visibility

-

Provides managers with live dashboards of stock levels

-

Enables dynamic allocation of resources and faster order fulfillment

-

Reduces stockouts and overstocking

3.6 Warehouse Automation

-

Integrates with automated guided vehicles (AGVs) and robotic systems

-

Facilitates pick-and-place automation using RFID-guided navigation

-

Reduces labor costs and operational errors

3.7 Loss Prevention and Security

-

Monitors item movement within restricted zones

-

Alerts when items are removed without authorization

-

Reduces theft and shrinkage

3.8 Shipping and Receiving Optimization

-

Automatically logs inbound and outbound shipments

-

Reduces manual scanning and paperwork

-

Enhances supply chain visibility for vendors and customers

4. Advantages of RFID Warehouse Inventory Management

4.1 Accuracy

RFID reduces errors caused by manual counting or barcode misreads. Inventory accuracy can increase from 60–70% to over 99%.

4.2 Speed and Efficiency

-

Rapid scanning of multiple items simultaneously

-

Reduces stocktaking time from days to hours

-

Enables real-time inventory updates

4.3 Cost Savings

-

Less manual labor required

-

Reduced stock discrepancies and write-offs

-

Improved warehouse space utilization

4.4 Enhanced Visibility

-

Track item location, quantity, and movement in real-time

-

Supports data-driven decision-making

-

Integrates with supply chain management for end-to-end transparency

4.5 Scalability

-

Systems can scale from small warehouses to large distribution centers

-

Additional readers and tags can be deployed as operations grow

4.6 Integration With Enterprise Systems

-

Integrates seamlessly with WMS, ERP, and IoT platforms

-

Supports predictive analytics and inventory optimization

4.7 Security and Compliance

-

Reduces risk of misplaced or lost items

-

Provides traceability for audit and regulatory compliance

-

Ensures proper handling of sensitive or controlled goods

5. Technical Components of RFID Warehouse Systems

5.1 RFID Tags

-

Passive, active, or semi-passive depending on application

-

Encoded with unique item IDs and optional data fields

5.2 RFID Readers

-

Fixed readers: Installed at entry/exit points, racks, or dock doors

-

Handheld readers: For spot checks, audits, and inventory reconciliation

5.3 Antennas

-

Directs RF signals to maximize read coverage

-

Configured for specific zones or tunnels for accurate detection

5.4 Middleware and Software

-

Collects data from readers

-

Filters duplicates and validates readings

-

Updates WMS or ERP in real-time

-

Provides analytics, dashboards, and alerts

5.5 Network Infrastructure

-

Wired or wireless connectivity

-

Ensures reliable data transmission and integration with cloud platforms

6. Implementation Considerations

6.1 Tag Selection

-

Match tag type to environment (metal, liquid, temperature)

-

Consider tag durability, adhesive strength, and read range

6.2 Reader Placement

-

Optimize coverage to avoid blind spots

-

Use zone mapping for racks, doors, and storage areas

6.3 Software Integration

-

Ensure compatibility with existing WMS, ERP, or IoT platforms

-

Configure alerts, reporting, and dashboards

6.4 Environmental Factors

-

Account for metal interference, liquids, and temperature extremes

-

Use specialized tags or shielding when necessary

6.5 Training and Change Management

-

Train warehouse staff on system use

-

Update standard operating procedures (SOPs)

-

Monitor adoption and resolve issues proactively

7. Challenges in RFID Warehouse Deployment

-

Initial cost: Hardware, software, and installation

-

Interference: Metals and liquids can reduce read accuracy

-

Tag collision: Multiple tags may cause data overlap if improperly configured

-

Maintenance: Reader calibration and tag replacement

-

Staff adaptation: Training and change management required

Despite these challenges, ROI is typically realized within months due to labor savings, accuracy gains, and operational efficiency.

8. Best Practices for RFID Warehouse Management

-

Pilot Testing: Start with a small section before full deployment

-

Optimize Tag Placement: Ensure visibility to readers

-

Regular Calibration: Maintain reader accuracy

-

Inventory Audits: Periodically verify RFID readings with manual counts

-

Integrate with ERP/WMS: Ensure smooth data flow and reporting

-

Leverage Analytics: Use real-time data for predictive stock replenishment

9. Case Studies

9.1 Retail Warehouse

A retail distribution center implemented UHF RFID tags on pallets and cartons, integrated with fixed readers and WMS. Results:

-

Inventory accuracy increased from 75% to 99%

-

Stocktaking time reduced by 80%

-

Reduced lost stock and order fulfillment errors

9.2 Pharmaceutical Storage

A pharmaceutical warehouse used temperature-sensitive RFID tags for cold chain management:

-

Monitored vaccine storage in real-time

-

Automated alerts for temperature deviations

-

Ensured regulatory compliance and reduced spoilage

9.3 E-commerce Fulfillment Center

-

Tagged all inventory with UHF RFID labels

-

Integrated with conveyor-based readers

-

Increased order picking speed by 50%

-

Minimized human errors and enhanced shipping accuracy

10. Future Trends in RFID Warehouse Inventory Tracking

-

IoT Integration: Real-time data sharing across supply chains

-

AI and Machine Learning: Predictive analytics for stock optimization

-

Blockchain Integration: Secure and transparent supply chain verification

-

Smart Sensors: Temperature, humidity, or shock monitoring integrated with RFID tags

-

Robotic Automation: RFID-guided picking, packing, and transport

-

Eco-Friendly Tags: Recyclable and sustainable RFID labels

The warehouse of the future will be highly automated, connected, and data-driven, powered by RFID technology.

11. ROI of RFID in Warehousing

Benefits include:

-

Reduced manual labor costs by up to 50%

-

Decreased inventory errors and losses

-

Faster order processing and fulfillment

-

Optimized storage space and warehouse layout

-

Enhanced supply chain visibility for better decision-making

Even with initial investment, RFID provides measurable operational and financial benefits within months.

12. Conclusion

RFID warehouse inventory tracking is transforming modern warehousing by enabling real-time visibility, automation, and accurate stock management. From item-level tracking to pallet and carton monitoring, RFID systems deliver efficiency, accuracy, and cost savings.

By leveraging advanced RFID tags, readers, middleware, and IoT integration, warehouses can:

-

Minimize errors

-

Improve throughput

-

Enhance operational efficiency

-

Ensure compliance and asset security

RFID is not just a technology—it is a strategic solution for smart warehousing. Businesses adopting RFID for inventory tracking gain a competitive advantage, streamline supply chains, and prepare for a future of fully automated and intelligent logistics.

The shift from manual inventory checks to RFID-enabled warehouse automation is no longer optional—it is essential for enterprises seeking accuracy, speed, and operational excellence.