RFID Warehouse Management & Inventory Control System

Warehouses are strange ecosystems. Thousands of objects move in and out. Humans scan. Forklifts move. Software updates. And somewhere between “received” and “shipped,” things disappear.

Not magically. Just inefficiently.

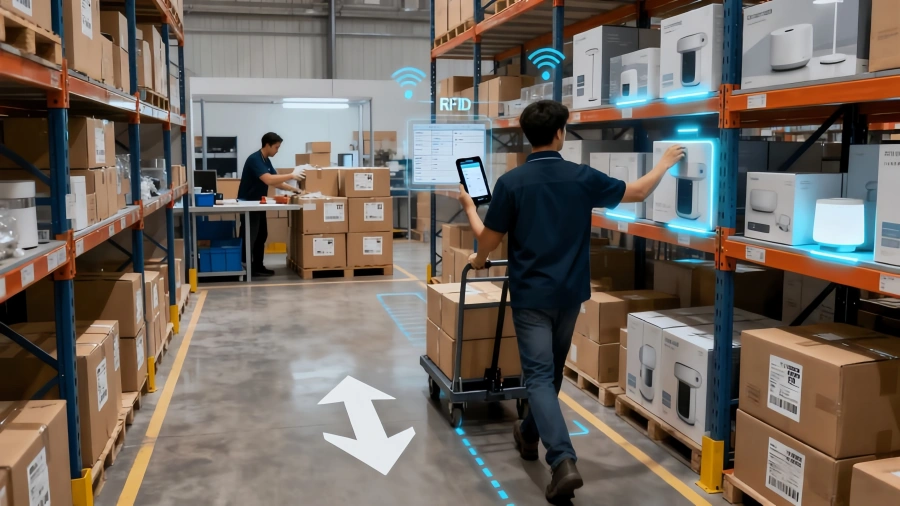

An RFID Warehouse Management & Inventory Control System replaces manual scanning and barcode-only workflows with automated, real-time identification using radio frequency technology. It allows businesses to track goods without direct line-of-sight scanning, reducing errors, saving labor, and increasing visibility across the entire supply chain.

This article explains, in clear and practical terms, how RFID works in warehouse environments, what components are required, how to implement the system correctly, and how it solves real operational pain points.

1. What Is an RFID Warehouse Management System?

An RFID Warehouse Management & Inventory Control System (RFID WMS) is a technology-driven solution that integrates:

- RFID tags

- RFID readers (fixed and handheld)

- Antennas

- Middleware

- Warehouse Management Software (WMS)

Together, these components enable automatic identification, tracking, and management of inventory without manual barcode scanning.

Instead of scanning one barcode at a time, RFID allows multiple items to be read simultaneously, even if they are inside cartons or on pallets.

If barcode is a flashlight, RFID is floodlight.

2. How RFID Works in Warehouse Operations

RFID stands for Radio Frequency Identification. It uses radio waves to transfer data between a tag attached to an item and a reader device.

There are three key parts:

- RFID Tag – Attached to goods, pallets, cartons, or containers.

- RFID Reader – Sends and receives radio signals.

- Software System – Processes and stores the data.

When goods pass through a reader’s detection zone, the tag responds automatically with its unique ID and stored data.

No direct line of sight is required.

This means items can be scanned:

- Inside sealed boxes

- On moving conveyor belts

- In bulk on pallets

- During forklift transport

3. Key Components of an RFID Warehouse System

3.1 RFID Tags

Common types:

- UHF (860–960 MHz) – Long range, ideal for warehouse and logistics

- HF (13.56 MHz) – Shorter range, used in item-level tracking

UHF tags are most common in warehouse systems because they support:

- 1–10 meters read range (depending on reader power)

- Fast anti-collision processing

- Bulk reading capability

Tags can be:

- Adhesive labels

- Hard tags

- Pallet tags

- Embedded in packaging

3.2 RFID Readers

There are two main types:

Fixed Readers

Installed at dock doors, conveyors, or entry points.

Handheld Readers

Used for mobile inventory counting and exception handling.

Fixed readers automate inbound and outbound tracking. Handheld devices assist with audits and verification.

3.3 Antennas

Antennas determine read zone shape and coverage. Proper antenna positioning is critical for accurate reads.

Poor antenna layout leads to:

- Missed reads

- Ghost reads

- Data confusion

RF engineering matters. Physics does not forgive sloppy installations.

3.4 Middleware and Integration Software

Middleware filters raw RFID data before sending it to the WMS.

Functions include:

- Duplicate filtering

- Time stamping

- Location mapping

- Event triggering

Without middleware, raw RFID data becomes overwhelming noise.

4. How RFID Improves Warehouse Processes

4.1 Inbound Receiving

Traditional process:

Workers scan each barcode manually.

RFID process:

Pallets pass through RFID gate.

All tagged items are automatically registered.

Benefits:

- Faster receiving

- Reduced labor

- Immediate inventory update

4.2 Put-Away and Storage

RFID enables location tracking.

When a forklift moves goods to a rack, the system updates inventory location automatically if readers are installed in zones.

This eliminates manual location entry errors.

4.3 Inventory Counting

Manual inventory takes hours or days.

With RFID:

- A handheld reader can scan hundreds of items in seconds.

- Entire warehouse zones can be scanned quickly.

- Cycle counts become efficient and accurate.

Inventory accuracy improves dramatically.

4.4 Order Picking

RFID systems guide pickers and confirm correct items are selected.

Benefits:

- Reduced picking errors

- Faster fulfillment

- Real-time confirmation

4.5 Outbound Shipping

As shipments leave the dock door, fixed readers verify:

- Correct items

- Correct quantities

- Correct shipment association

Shipping errors decrease significantly.

5. Real Industry Pain Points Solved by RFID

Pain Point 1: Inventory Inaccuracy

Manual scanning errors accumulate over time.

RFID improves accuracy to 98–99% in optimized systems.

Pain Point 2: Labor-Intensive Processes

Warehouse labor is expensive.

RFID reduces:

- Manual scanning time

- Physical counting workload

- Data entry effort

Pain Point 3: Shrinkage and Loss

Misplaced or stolen inventory creates financial loss.

RFID provides:

- Real-time visibility

- Movement tracking

- Audit trails

Pain Point 4: Slow Order Fulfillment

Barcode scanning slows picking lines.

RFID accelerates verification and reduces bottlenecks.

Pain Point 5: Lack of Real-Time Visibility

Traditional systems update inventory after manual confirmation.

RFID updates inventory instantly.

6. Benefits of RFID Warehouse Management System

Increased Inventory Accuracy

Accurate stock levels reduce stockouts and overstocking.

Faster Operations

Bulk scanning speeds up:

- Receiving

- Shipping

- Audits

Improved Supply Chain Transparency

Real-time tracking enables better forecasting and planning.

Reduced Human Error

Automation reduces reliance on manual data entry.

Scalability

RFID systems can expand across multiple warehouses and regions.

7. Comparison: RFID vs Barcode in Warehousing

| Feature | RFID | Barcode |

|---|---|---|

| Line of Sight Required | No | Yes |

| Bulk Reading | Yes | No |

| Read Speed | High | Manual |

| Durability | High | Label can fade |

| Automation | High | Limited |

Barcodes are simple and cheap.

RFID is automated and scalable.

They can coexist, but RFID unlocks higher efficiency.

8. Implementation Strategy for RFID Warehouse System

Step 1: Feasibility Study

Analyze:

- Warehouse layout

- Product types

- Metal/liquid interference

- Required read range

Step 2: Tag Selection

Choose tags based on:

- Environment

- Material type

- Read range

- Mounting method

Metal and liquid environments require special tag design.

Step 3: Reader and Antenna Layout Design

Plan:

- Dock door portals

- Conveyor tunnels

- Shelf-level coverage

- Forklift-mounted readers (optional)

Engineering planning prevents later problems.

Step 4: Software Integration

Integrate RFID middleware with:

- Existing WMS

- ERP system

- Inventory databases

Data flow must be structured.

Step 5: Pilot Testing

Run a small-scale deployment before full rollout.

Test for:

- Read accuracy

- Data consistency

- Workflow impact

Step 6: Full Deployment

Train staff and monitor performance metrics.

9. Challenges and How to Overcome Them

Challenge 1: Metal and Liquid Interference

UHF signals reflect off metal and are absorbed by water.

Solution:

Use specialized anti-metal tags and proper antenna positioning.

Challenge 2: Initial Investment

RFID requires higher upfront cost than barcode systems.

Solution:

ROI analysis typically shows labor savings and error reduction offset investment within 1–3 years.

Challenge 3: Data Overload

Too much raw data can overwhelm systems.

Solution:

Use intelligent middleware filtering.

10. ROI of RFID Warehouse Systems

Key financial benefits:

- Reduced labor costs

- Lower shrinkage

- Fewer shipping errors

- Faster order processing

- Improved customer satisfaction

Companies often report:

- 20–30% labor savings

- 50% reduction in counting time

- 99% inventory accuracy

Efficiency compounds over time.

11. Industries Benefiting from RFID Warehouse Systems

- E-commerce fulfillment centers

- Automotive parts warehouses

- Pharmaceutical distribution

- Apparel and retail

- Electronics manufacturing

- Aviation logistics

- Cold chain storage

Any environment with high SKU volume benefits.

12. Practical Tips for Buyers

When selecting an RFID warehouse system, consider:

- UHF frequency compliance (regional regulations)

- Tag durability requirements

- Scalability potential

- Integration compatibility

- Technical support availability

- Future expansion needs

Avoid choosing solely based on price.

RFID success depends on system design, not just hardware.

13. Future Trends in RFID Warehouse Technology

Emerging developments include:

- RFID + IoT integration

- Cloud-based WMS platforms

- AI-powered inventory forecasting

- Smart shelves with embedded readers

- Autonomous robots integrated with RFID

Warehouses are becoming intelligent ecosystems.

Inventory is no longer static. It becomes live data.

14. Conclusion

An RFID Warehouse Management & Inventory Control System transforms warehouse operations from manual and reactive to automated and real-time.

It enables:

- Accurate inventory tracking

- Faster receiving and shipping

- Reduced labor dependency

- Scalable growth

- Real-time operational visibility

While implementation requires thoughtful planning and engineering, the long-term operational gains are substantial.

Warehouses are complex systems. Complexity demands precision. RFID provides that precision invisibly, through radio waves moving faster than any scanner beam.

Goods move. Readers detect. Software updates.

No drama. Just data.

And in modern logistics, data accuracy is not optional. It is competitive survival.

When inventory becomes visible in real time, decisions become smarter.

When errors decrease, margins improve.

When operations accelerate, customers notice.

RFID does not replace warehouses.

It upgrades them.